Heavy-duty blades for trucks and buses

Unique stiffness and rigidity of Motgum's truck wiper blades are achieved by using thick steel frame and riveted joints. This is critical for long wipers blades carrying large profile rubbers used in heavy vehicles such as buses, buliding machinery or even trains. Thanks to a complete adaptor system our wiper blades can be mounted on virtually any truck or bus manufactured anywhere in the world.

Technical data:

Anti-corrosion resistance: above 480 hours (salt chamber test, specifications in acc. with ASTM B – 117).

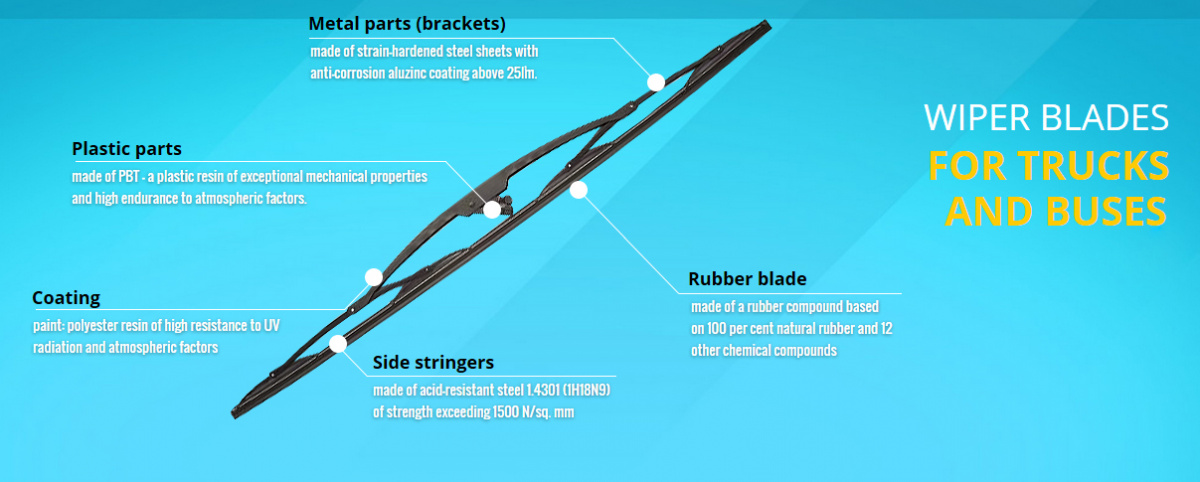

Rubber blade – made of a rubber compound based on 100 per cent natural rubber and 12 other chemical compounds with addition of graphite which improves friction factor and prevents noisy wiper operation. A unique technology of adding graphite on the compound level – rather than spraying it on the surface – eliminates any residue on the windscreen. MOTGUM rubbers blades comply with respective FIAT and GM norms regarding mechanical properties, wiping quality and ozone resistance.

Side springs – made of acid-resistant steel 1.4301 (1H18N9) of strength exceeding 1500 N/sq. mm.

Metal parts (brackets) – made of strain-hardened steel sheets with anti-corrosion aluzinc coating above 25ľm.

Plastic parts – made of PBT (Polybutylene Terephthalate) – a plastic resin of exceptional mechanical properties and high endurance to atmospheric factors.

Coating – paint: polyester resin of high resistance to UV radiation and atmospheric factors (salts, acids, exhaust pollution).

Dotacja na kapitał obrotowy dla MOTGUM Sp.j. Perczyński Godlewski Kukla

Dotacja na kapitał obrotowy dla MOTGUM Sp.j. Perczyński Godlewski Kukla

Projekt dotyczący wsparcia przedsiębiorcy w zakresie zapewnienia płynności finansowej oraz wsparcia bieżącej działalności w związku z trudnościami finansowymi, które wystąpiły u przedsiębiorcy wskutek epidemii COVID-19. Pomoc finansowa udzielana na podstawie programu nr SA.57015 (2020/N).